Product Introduction and Feature

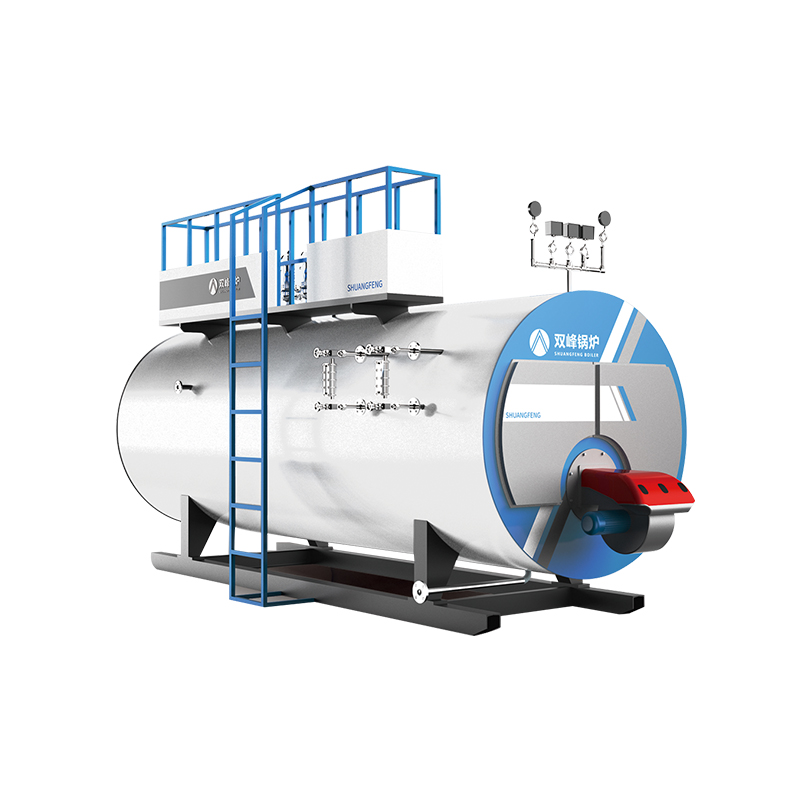

WNS series fuel (gas) boilers are designed, manufactured, inspected, and guaranteed to meet the safety technical supervision regulations and relevant standards for steam and hot water boilers to ensure the safe use of the products.

The furnace body structure is optimally designed, providing a large heating surface area. It features a typical horizontal three-pass wet-back structure, which not only improves efficiency but also reduces the generation of nitrogen oxides and lowers the emission of harmful substances in the smoke and dust.

Equipped with a computer-based automatic control system with self-diagnostic function, the boiler automatically shuts down and alerts with sound and light when abnormal operation occurs, indicating the cause of the fault for convenient maintenance.

The boiler uses world-renowned brand burners, which automatically adjust the heat output according to the load, and have flame detection and automatic purging functions, making management extremely convenient and reducing operational costs while achieving excellent environmental protection results.

The compact exterior size of the boiler makes it aesthetically pleasing and easy to install. The overall sealing is excellent, reducing smoke leakage and heat energy loss.

The threaded smoke tubes enhance heat transfer, reduce the size of the shell, and increase flexibility, thereby reducing the thermal stress at the tube ends, preventing ash accumulation, and preventing cracking of the tube sheet.

The corrugated furnace is conducive to thermal expansion, increasing the heating surface area of the furnace body and effectively improving the boiler's thermal efficiency.

The full wet-back type combustion chamber ensures effective cooling and uniform stress distribution on the tube sheet.

| Item/Model/Unit | WNS 1-1.0 -Y(Q) |

WNS 1-1.25 -Y(Q) |

WNS 1.5-1.25 -Y(Q) |

WNS 2-1.0 -Y(Q) |

WNS 2-1.25 -Y(Q) |

WNS 3-1.25 -Y(Q) |

WNS 4-1.25 -Y(Q) |

WNS 5-1.25 -Y(Q) |

WNS 6-1.25 -Y(Q) |

WNS 8-1.25 -Y(Q) |

WNS 10-1.0 -Y(Q) |

WNS 10-1.25 -Y(Q) |

WNS 10-1.6 -Y(Q) |

WNS 15-1.25 -Y(Q) |

WNS 15-1.6 -Y(Q) |

WNS 20-1.25 -Y(Q) |

|

| Transpiration rate | MW | 1 | 1 | 1.5 | 2 | 2 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 10 | 15 | 15 | 20 |

| Working pressure | Mpa | 1 | 1.25 | 1.25 | 1 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1 | 1.25 | 1.6 | 1.25 | 1.6 | 1.25 |

| Staem temp | ℃ | 184 | 193 | 193 | 184 | 193 | 193 | 193 | 193 | 193 | 193 | 184 | 193 | 204 | 193 | 204 | 193 |

| Water Supplytemp | ℃ | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 105 | 105 | 105 | 105 | 105 | 105 |

| Heating Area | ㎡ | 30.5 | 30.5 | 39.5 | 49.5 | 49.5 | 75 | 113 | 146 | 183 | 232 | 293.6 | 293.6 | 293.6 | 410 | 410 | 530 |

| FuelAvailable | Heavy oil, light oil, natural gas, liquefied gas, urban gas | ||||||||||||||||

| Oil(Gas) consumption |

kg/h (Nm³/h) |

65 (76) |

68 (77) |

97.5 (113) |

130 (149) |

130.5 (150) |

195 (226) |

260 301) |

325 (380) |

391 (452) |

449 (532) |

629 (706) |

630 (708) |

632 (710) |

945 (1062) |

947 (1064) |

1260 (1418) |

| Designed Effciency | ㎡ | ≥100.5 | ≥100.5 | ≥100.5 | ≥100.5 | ≥100.5 | ≥100.5 | ≥100.5 | ≥100.5 | ≥100.5 | ≥100.5 | ≥100.8 | ≥100.8 | ≥100.8 | ≥100.8 | ≥100.8 | ≥100.8 |

| Transport dimension |

mmxmm mxmm |

3500x18 40x2022 |

3500x18 40x2022 |

3920x20 60x2340 |

4350x20 60x2473 |

4350x20 60x2473 |

4400x21 50x2500 |

5540x23 00x2600 |

5710x24 00x2650 |

6320x25 40x2944 |

6800x31 00x3500 |

7200x32 00x3600 |

7200x32 00x3600 |

7200x32 00x3600 |

7900x33 20x3742 |

7900x33 20x3742 |

8250x35 00x4300 |

| Transport Weigtiel Large Picces |

t | 4.9 | 6.1 | 75 | 8 | 9 | 12 | 14.9 | 16 | 19 | 26 | 27 | 29 | 31 | 40.5 | 43 | 51 |