Product Introduction and Feature

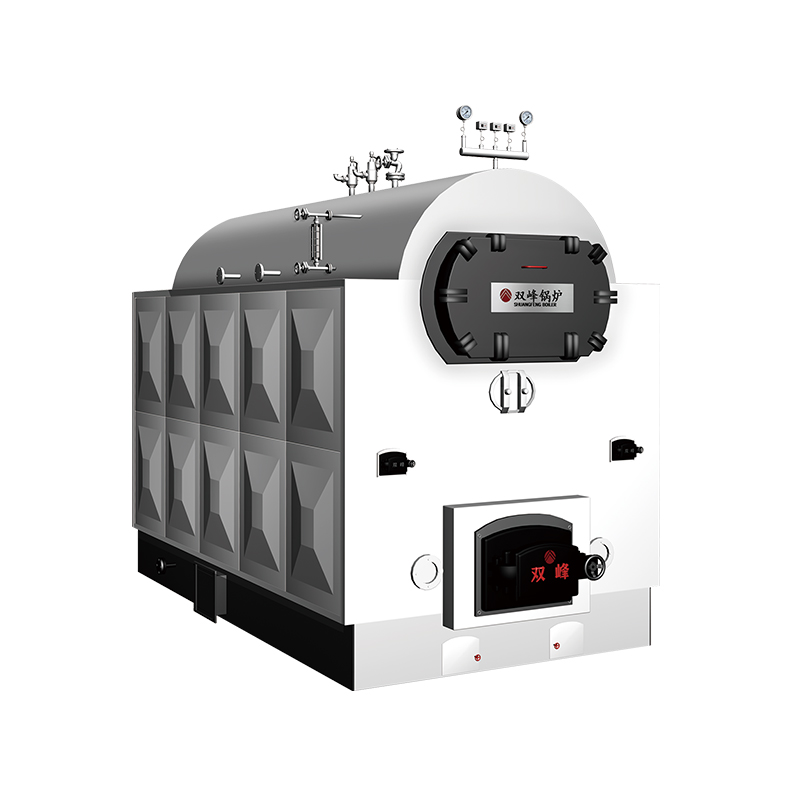

DZG structure coal-fired steam boiler features a compact and single-layer layout with threaded smoke tubes and smokeless combustion technology, ensuring safety, reliability, and significant energy savings with high thermal efficiency.

Boiler adopts a single-layer grate for combustion, providing strong fuel adaptability, excellent combustion performance, and easy operation.

The arrangement of the three-pass heating surface ensures proper water circulation and heat exchange, achieving optimal heat transfer efficiency and ample boiler output.

The boiler system comprises a waste heat water tank, dust collector, flue, induced draft fan, forced draft fan, pipeline valves, instruments, and chimney.

It has a wide fuel adaptability and stable combustion. The reasonable combination of front and rear arches organizes the air dynamics in the furnace, allowing more complete combustion and heat exchange.

Smokeless combustion technology is employed, and a carefully designed secondary air device arranges secondary and tertiary air at different heights within the furnace. This disturbs the air and flue gas, ensuring ample contact and supplying the necessary oxygen for complete combustion, effectively reducing smoke and dust in the furnace.

The boiler has a thick insulating layer, minimizing heat loss from the furnace body.

It is aesthetically pleasing with stylish external packaging and an easy-to-assemble form, making transportation and installation convenient.

The boiler comes with comprehensive supporting facilities, fast factory assembly, short installation period, and a single-layer layout for the boiler room, reducing installation infrastructure investment and overall cost.

DZG-Stype Biomass Fired Boiler

| Unbjects | UNIT | DZG1-1.0/1.25-S | DZG2-1.0/1.25-S | DZG3-1.0/1.25-S | DZG4-1.25/1.6-S | |

| Steam capacity | (T/h) | 1 | 2 | 3 | 4 | |

| Working pressure | (MPa) | 1.0/1.25 | 1.0/1.25 | 1.0/1.25 | 1.25/1.6 | |

| Steam Temperature | ℃ | 184/194 | 184/194 | 184/194 | 194/204 | |

| Feedwater Temperature |

℃ | 20 | 20 | 20 | 20 | |

| Heating Area |

Boiler proper | m² | 36.5 | 74.3 | 98.5 | 121 |

| Economizer | m² | 21.1 | 28.16 | 38.3 | 38.3 | |

| Grate Arer | m² | 1.4 | 2.52 | 2.52 | 3.9 | |

| Design Heating Efficiency |

% | 84 | 84 | 85 | 85 | |

| Design Fuel | (Wood)bamboo chips, wood (bamboo)chips, biomass particles | |||||

| Overall Dimensions (LXWXH)) |

mm | 4300×2100Z×2850 | 4900×2600×3050 | 5500×2600×3300 | 5900×2800×3640 | |

| Weight of boiler ptoper |

T | ~14.6/14.8 | ~17.5/17.8 | ~22/23 | ~32/33 | |