Product Introduction and Feature

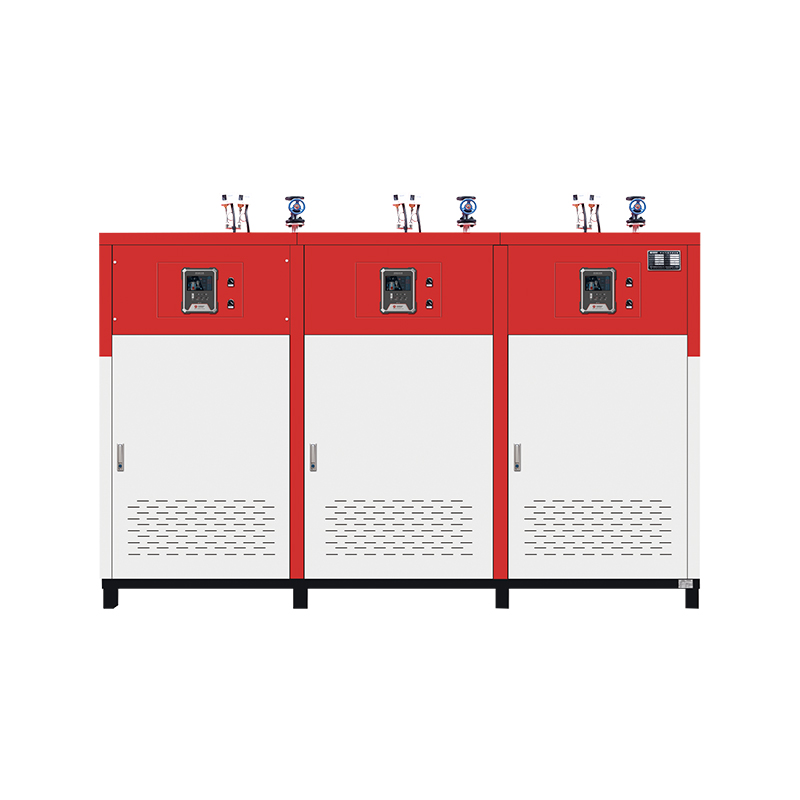

SFeng LHS Industrial Automatic Gas/Oil-fired Steam Generator is a steam generator that uses natural gas (diesel) as fuel to produce steam. The boiler adopts a unique positive pressure combustion technology and is equipped with a condensing economizer. The flue gas is recycled through multiple passages, and the condenser heats the water, achieving heat recovery, lowering the

exhaust gas temperature, and increasing the boiler efficiency. The product has high efficiency, fast steam output, and stable gas pressure during use. The equipment's outer shell is made of high thermal resistance fibers and enclosed metal casing for insulation, ensuring convenient fabrication, maintenance, and repair.

Features:

1. One-click operation, remote control via mobile phone, fully automatic microcomputer control for operation, and real-time data monitoring through remote control.

2. Comprehensive protection system: with overpressure, water shortage, anti-dry-burning, and other interlocking protection devices.

3. Dual-module combination, automatically adjusting the number of modules based on steam volume, and featuring a one-to-one backup function.

4. Fast steam output, capable of producing steam in three minutes, enabling immediate use and instant shutdown to reduce heat loss.

5. Unique condenser and economizer device, achieving thermal efficiency of over 97%, and exhaust gas temperature below 100°C.

Applications:

Foam industry, packaging industry, wood board industry, drying industry, washing industry, garment factories, sock factories, hotels, restaurants, tableware disinfection companies, electroplating industry, chemical industry, adhesive industry, etc.

| Project/Model/Unit | LHS0.1-0.7-Y(Q) | LHS0.15-0.7-Y(Q) | LHS02-0.7-Y(Q) | LHS0.3-0.7-Y(Q) | LHS0.5-0.7-Y(Q) | LHS0.6-0.7-Y(Q) | LHS0.7-0.7-Y(Q) | LHS1.0-0.7-Y(Q) | |

| Rated evaporation | kg/h | 100 | 150 | 200 | 300 | 500 | 600 | 700 | 1000 |

| Hghest pressure | Mpa | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| Hghest temperature |

℃ | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 |

| Themal effidiency | % | 96 | 96 | 97 | 97 | 97 | 97 | 97 | 97 |

| Olconsumption | kg(Nm³/h) | 5.8(7.6) | 9(12) | 12(15) | 17(22.8) | 29(38) | 35(46) | 40.6(53.2) | 58(76) |

| Applicable fuel | Natural gas/diesel liquefied gas/alcohol based |

Natural gas/diesel liquefied gas/alcohol based |

Natural gas/diesel liquefied gas/alcohol based |

Natural gas/diesel liquefied gas/alcohol based |

Natural gas/diesel liquefied gas/alcohol based |

Natural gas/diesel liquefied gas/alcohol based |

Natural gas/diesel liquefied gas/alcohol based |

Natural gas/diesel liquefied gas/alcohol based |

|

| Product size | mm | 1100×1050×2000 | 1300×1050×1870 | 1220×1650×2300 | 1270×1650×2300 | 2300×1750x2450 | 2300x1750x2450 | 2400×2100x2600 | 3200×2200×2300 |

| Boler water volume | L | 26 | 28 | 28 | 29 | 29 | 29 | 29 | 29 |

| Boler water volume | kg | 1000 | 1100 | 1350 | 1350 | 2700 | 2700 | 3650 | 4330 |

| Power consumpton | kw/h | 1.5 | 1.7 | 2.2 | 2.5 | 4.2 | 4.5 | 5 | 7 |

| Working pressure | Mpa | 0-0.7 | 0-0.7 | 0-0.7 | 0-0.7 | 0-0.7 | 0-0.7 | 0-0.7 | 0-0.7 |

| Working mode | single moduel | single moduel | single moduel | single moduel | Dual-module | Dual-module | Dual-module | Dual-module | |