Product Introduction and Feature

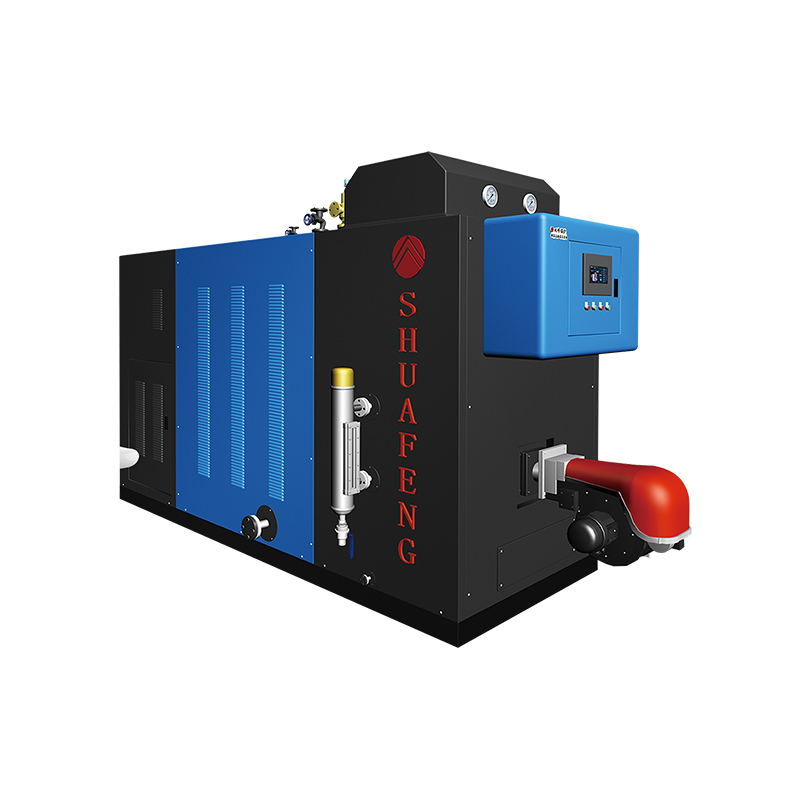

The SFeng SZS-Q series condensing gas/oil-fired steam generator is a product that uses natural gas (diesel, LNG) as fuel to produce steam. The product adopts German frequency conversion steam technology and features a dual-drum vertical arrangement structure. The main material used is a superconductive finned tube with a thermal conductivity several times higher than regular tubes. The equipment utilizes micro-positive pressure combustion, and the burner (imported brand) releases flames that fully combust inside the furnace. The flue gas then passes through the radiation

heat exchanger (flue gas circulation), convection tube bundle, and condensing economizer before being discharged into the chimney (furnace's horizontal three-pass + external condensing economizer configuration). This process achieves the release of flue gas sensible heat and water vapor condensation latent heat, allowing the condenser's water to absorb heat and be heated. Consequently, heat recovery is achieved, and the thermal efficiency of the evaporator is increased.

The equipment's body and the area around the furnace are enclosed in a membrane wall, which not only increases the heating surface area but also ensures a reliable seal to prevent flue gas leakage. Additionally, a lightweight furnace wall is employed, ensuring reliable operation, minimal heat loss, low thermal inertia, and quick start-stop capabilities.

The steam generator's outer shell is insulated with high thermal resistance fibers and enclosed metal casing, with thorough consideration for easy operation, maintenance, and repair during the design process.

The product is delivered as a modular unit with a small footprint, low installation site requirements, and one-click operation, ensuring safety and ease of use. Our company's steam generator has a lifespan over three times longer than those available in the market.

| Model | unit | SZS0.5-0.8-Q | SZS0.7-0.8-Q | SZS1.0-0.8-Q | SZS1.5-0.8-Q | SZS2.0-0.8-Q |

| Rated evaporation | kg/h | 500 | 700 | 1000 | 1500 | 2000 |

| Maximum pressure | Mpa | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Rated temperature | ℃ | 175 | 175 | 175 | 175 | 175 |

| Thermal efficiency | % | 98 | 98 | 98 | 98 | 98 |

| Full load fuel consumption |

Nm³/h | 38 | 54 | 76 | 114 | 152 |

| Average fuel consumption |

Nm³/h | 26.6 | 37.8 | 53.2 | 79.8 | 106.4 |

| Product size | mm | 2600×1400×1800 | 2800×1500×2000 | 3200×1600×2200 | 2800×2650×2000 | 3200×2950×2200 |

| Product weight | kg | 1700 | 1900 | 2500 | 3500 | 4500 |

| Power consumption | kw/h | 3 | 4 | 5 | 8 | 10 |

| Working pressure | Mpa | 0-0.8 | 0-0.8 | 0-0.8 | 0-0.8 | 0-0.8 |