Product Introduction and Feature

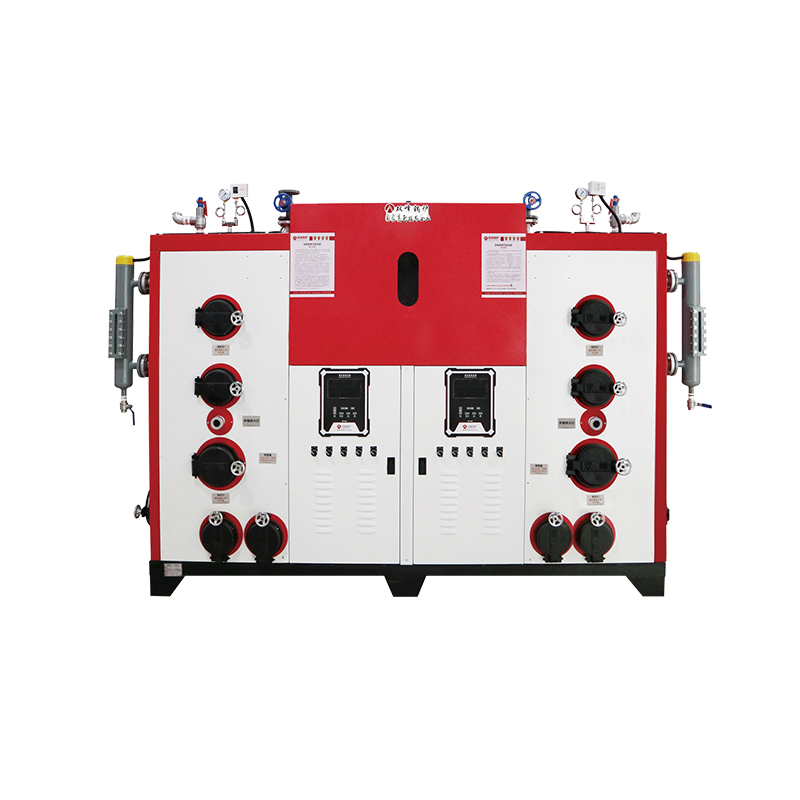

The SFeng LHG-s series biomass coal fired steam generator is a semi-gasification fire-tube steam generator that uses biomass pellets as fuel to produce steam. The boiler employs a unique micro-positive pressure combustion technology and is equipped with double economizers and an external water membrane dust remover. It incorporates a secondary air supply for suspended semi-gasification combustion technology, achieving a biomass combustion efficiency of up to 99.9%. The flue gas is recycled through multiple passages, increasing the heating surface area by 30% and significantly enhancing the boiler's thermal efficiency. The biomass steam generator meets environmental requirements in various regions and produces no smoke or dust after normal combustion. The outer shell is constructed with high thermal resistance fibers and an enclosed metal casing as insulation, with careful consideration for ease of operation, maintenance, and repair during the design process.

Key Features:

1. Patented and aesthetically appealing exterior design.

2. 7-inch large screen (waterproof and dustproof).

3.WeChat mini-program for power on/off and parameter modification.

4. Stable and safe 24V voltage output.

5. Water quality detection function to ensure the boiler meets standards (optional).

6. Flue gas temperature detection function for double protection against dry burning (optional).

7. Four-level firepower adjustment for simple and convenient operation.

8. Customers can remotely power on/off the boiler, modify parameters, monitor usage, and receive automatic SMS alarms through their mobile phones, achieving true unattended operation.

The product is delivered as a complete unit with a small footprint, low installation site requirements, and one-click operation, ensuring safety and ease of use. Our company's steam generator has a lifespan over three times longer than those available in the market.

Parameter Table Of Biomass Steam Generator

| Product brand | Shuangfeng boiler | Shuangfeng boiler | Shuangfeng boiler | Shuangfeng boiler | Shuangfeng boiler | Shuangfeng boiler | Shuangfeng boiler | Shuangfeng boiler | Shuangfeng boiler | Shuangfeng boiler | |

| Model/Project/Unit | LHG0.1-0.7-S | LHG0.12-0.7-S | LHG0.15-0.7-S | LHG02-0.7-S | LHG025-0.7-S | LHG0.3-0.7-S | LHG0.35-0.7-S | LHG0.5-0.7-S | LHG0.6-0.7-S | LHG0.7-0.7-S | |

| Rated evaporation | kg | 100 | 120 | 150 | 200 | 250 | 300 | 350 | 500 | 600 | 700 |

| Highest pressure | Mpa | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| Hghest temperature | ℃ | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 |

| Boler water volume | L | 26 | 26 | 28 | 28 | 29 | 29 | 29 | 29 | 29 | 29 |

| Product size | mm | 1280×950×2500 | 1400×1150×2500 | 1580×1280×2400 | 1500x1300x2100 | 1800×1250×2100 | 1600×1450×2100 | 1650×1500×2200 | 2650×1500×2100 | 2900×1480×2200 | 3200×1500×2300 |

| Bolerwater volume | kg | 600 | 650 | 800 | 880 | 1100 | 1200 | 1300 | 2100 | 2200 | 2400 |

| Themal eficiency | % | 88 | 88 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Full load fuel consumption | kg/h | 16 | 19 | 24 | 32 | 40 | 48 | 56 | 79 | 95 | 110 |

| Average fuel consumption |

kg/h | 11 | 14 | 17 | 22 | 28 | 33 | 39 | 56 | 67 | 77 |

| Hopper capacity | kg | 65 | 72 | 110 | 150 | 160 | 180 | 200 | 330 | 360 | 380 |

| Power consumption | kw/h | 0.7 | 0.78 | 0.88 | 0.95 | 1.1 | 1.2 | 1.4 | 2.2 | 2.5 | 3 |

| Working pressure | Mpa | 0-0.7 | 0-0.7 | 0-0.7 | 0-0.7 | 0-0.7 | 0-0.7 | 0-0.7 | 0-0.7 | 0-0.7 | 0-0.7 |

| Working mode | stand-alone | stand-alone | stand-alone | stand-alone | stand-alone | stand-alone | stand-alone | oombination | combination | combination | |