Product Introduction and Feature

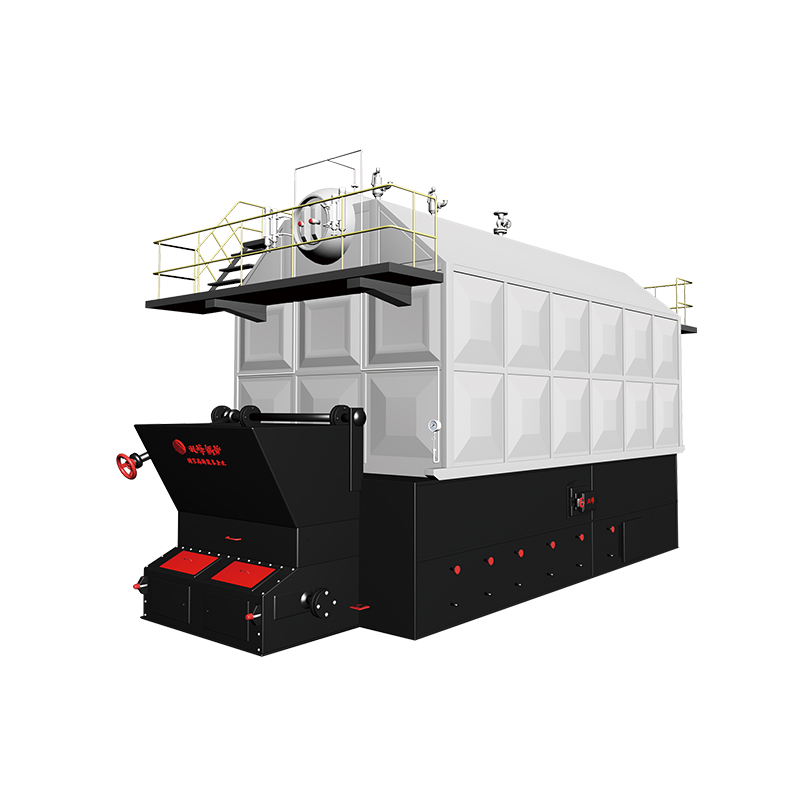

SZI-S type energy-saving and environmentally friendly steam boiler is a new product developed by our company to replace traditional biomass chain grate boilers. The product utilizes four patented technologies, and the company holds independent intellectual property rights. All economic and technical indicators are at the forefront of similar domestic products. The product features are as follows:

1. The boiler structure adopts a symmetrical O-type arrangement, presenting an attractive appearance and ensuring convenient operation, maintenance, and safe and reliable operation. The boiler offers good controllability and stable combustion.

2. The boiler has ample heating surface area. The convection tube bundle is swept by the flue gas in a horizontal direction, and the flue gas flows in a straight line from the inlet of the first convection tube bundle to the outlet of the second tube bundle, resulting in uniform gas sweeping, a large heat transfer coefficient, low flue gas flow resistance, and thorough heat exchange.

3. The boiler is equipped with an ash chamber at the rear of the furnace, increasing the radiant heating surface area and prolonging the flow of flue gas, ensuring sufficient combustion and heat exchange.

4. Large-diameter downcomers and a well-designed water circulation system ensure good water circulation in the boiler.

5. The boiler has a large water volume and strong load adaptability.

6. The lower drum can freely expand backward, and the whole body can freely expand upward. The body structure is

symmetrical, ensuring even expansion and avoiding the generation of thermal stresses due to expansion.

7. The grate has a large combustion area, promoting thorough fuel combustion and reducing solid incomplete combustion losses.

8. The boiler uses manual ignition and mechanical feeding. Biomass granules are continuously and uniformly fed to the boiler through a specially designed hydraulic pusher by "Shuangfeng."

9. High-quality grate plates are used, providing uniform air supply and minimizing material leakage. This overcomes the shortcomings of conventional grate plates, such as high failure rate, easy fracture, burnout, complex maintenance, severe material leakage, and poor self-cleaning ability.

10. The boiler adopts compartmentalized air supply with dual-side distribution, ensuring uniform and rational ventilation and broad fuel adaptability with stable combustion. The reasonable combination of front and rear arches organizes the air dynamics in the furnace, facilitating more complete combustion and heat exchange.

11. Smokeless combustion technology is employed, and a carefully designed secondary air device arranges secondary and tertiary air at different heights within the furnace. This disturbs the air and flue gas, ensuring ample contact and supplying the necessary oxygen for complete combustion, effectively reducing smoke and dust in the furnace.

12. The boiler has a thick insulating layer, minimizing heat loss from the furnace body. It is aesthetically pleasing with a stylish external packaging and easy-to-assemble form, making transportation and installation convenient. The boiler room is arranged in a single-layer layout, reducing infrastructure investment.

SZL -Series Biomass Steam Boiler

| Date/Model/Parameters |

SZL10-125-S SZL10-1.6-S SZL10-245-S |

SZL15-1.25-S SZL15-16-S SZL15-245-S |

SZL20-125-S SZL20-16-S SZL20-245-S |

SZL25-125-S SZL25-1.6-S SZL25-2.45-S |

||

| Steam capacity | t/h | 10 | 15 | 20 | 25 | |

| Working pressure | MPa | 1.251.6245 | 125/1.6245 | 1.251.6245 | 125/1.6245 | |

| Steam Temperature | ℃ | 193204225 | 193/204225 | 193204/225 | 193/204225 | |

| Feedwater Temperature | ℃ | 105 | 105 | 105 | 105 | |

| Boiler Heat area |

The area of radiation | ㎡ | 288 | 38.1 | 743 | 1136 |

| Convection control | ㎡ | 2299 | 314 | 3385 | 358.5 | |

| Waste heat water tank | ㎡ | 81.8 | 151.4 | 221 | 297 | |

| Air Preheater | ㎡ | 121.3 | 183.6 | 246 | 443.4 | |

| Grate Arer | ㎡ | 14.7 | 18.43 | 22.6 | 26.7 | |

| Adaptation of fuel |

Design Fuel | Bomass paticles | ||||

| Low heat | kcal/kg | 4077 | ||||

| Design Heating Effciency | % | 86 | 86 | 87 | 87 | |

| Boiler fuel consumption | kgh | 1604 | 2405 | 3170 | 3962 | |

| Hot air temperature | ℃ | 104 | 82 | 80 | 129 | |

| Gas temperature | ℃ | 163 | 160 | 160 | 157 | |

| Boler after the hstallafion of mainframe appearanoe Dimonsions(LXWXH) |

m | 14.2X4.2X62 | 16X6.5X6.6 | 20.7X6.7X7.5 | 16.3X7X11 | |