Product Introduction and Feature

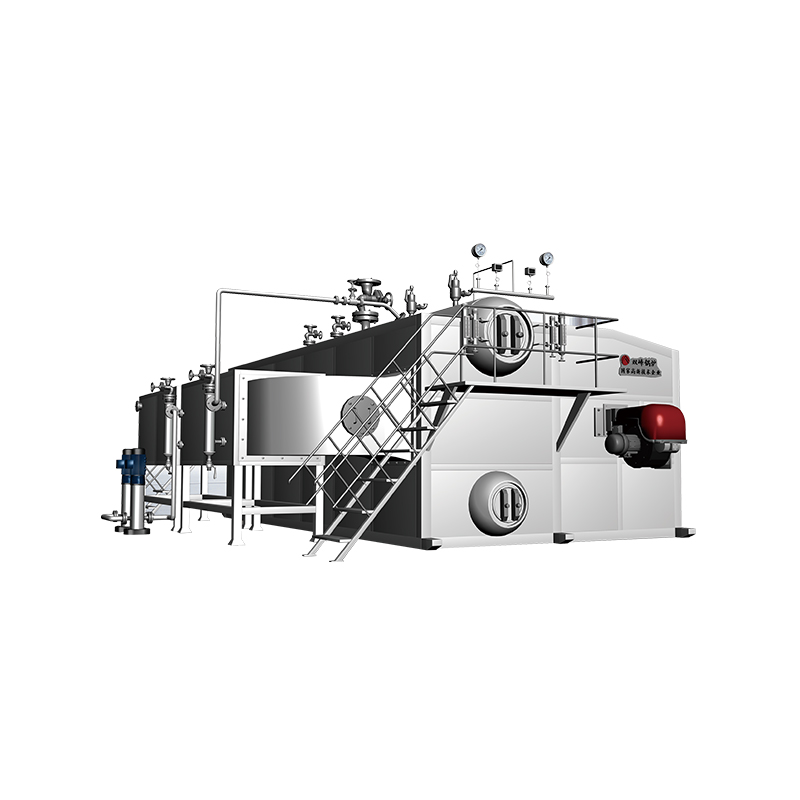

The SZS water tube fuel gas fired steam boiler adopts a double-drum vertical D-type furnace structure, with energy-saving devices placed at the tail for additional heating surface. The burner is arranged on the front wall, and the convection tube bundles are placed parallel to the furnace. The combustion gases pass through the rear of the furnace and flow successively through the heater (if present), convection tube bundles, and the rear heating surface before being discharged into the atmosphere through the chimney.

Main features of the boiler body structure:

The design of the double-drum vertical D-type layout ensures good stress conditions for the pressure-bearing components of the boiler. Important pressure-bearing elements such as the drum are not directly exposed to high-temperature flame radiation and abrasion, allowing for easy expansion and contraction and reducing thermal stress, thus achieving higher safety levels.

Control system features of the SZS series fuel (gas) steam boiler:

Intelligent control system:

The PLC control system adopts a programmable controller (PLC) as the central controller, with a full Chinese display touch screen as the operating terminal, capable of real-time display of all system parameter data, boiler operation dynamic screens, and more.

PID regulation: Fully automatic control of boiler start, ignition, combustion, and PID calculation for proportional control of combustion load and temperature control targets (steam boiler control pressure, hot water boiler control outlet temperature).

Frequency conversion control: The boiler feedwater system adopts frequency conversion control for continuous feedwater supply, and the induced draft fan system and other components also use frequency conversion control.

Chain lock protection: The system has multiple interlocking protections, such as ultra-high pressure, extremely low water level, ignition failure, fault flameout, abnormal gas pressure, leakage failure, overload of fan and water pump, etc.

| Item/Unit/Model | SZS4- 2.45-Y(Q) |

SZS6- 2.45-Y(Q) |

SZS10- 1.25/(1.6)-Y(Q) |

sZS10- 1.25/250-Y(Q) |

SZS10- 2.45/400-Y(Q) |

SZS15- 1.25/(1.6)-Y(Q) |

SZS15- 1.25/250-Y(Q) |

SZS15- 2.45/400-Y(Q) |

SZS20- 1.25/(1.6)-Y(Q) |

SZS20- 1.25/250-Y(Q |

SZS20 2.45/400-Y(Q) |

SZS25- 125/(1.6)-Y(Q) |

SZS25- 1.25/250-Y(Q) |

SZS25- 2.45/400-Y(Q) |

SZS35- 1.25/(1.6)-Y(Q) |

SZS35- 1.25/250-Y(Q) |

SZS35- 2.45/400-Y(Q) |

|

| Transpiration rate | T/H | 4 | 6 | 10 | 10 | 10 | 15 | 15 | 15 | 20 | 20 | 20 | 25 | 25 | 25 | 35 | 35 | 35 |

| Working Pressure | Mpa | 2.45 | 2.45 | 1.25(1.6) | 1.25 | 2.45 | 1.25(1.6) | 1.25 | 2.45 | 1.25(1.6) | 1.25 | 2.45 | 1.25(1.6) | 1.25 | 2.45 | 1.25(1.6) | 1.25 | 2.45 |

| Steam Temp | ℃ | 225 | 225 | 193(204) | 250 | 400 | 193(204) | 250 | 400 | 193(204) | 250 | 400 | 193(204) | 250 | 400 | 193(204) | 250 | 400 |

| Water supply Temp | ℃ | 20 | 20 | 105 | ||||||||||||||

| Disign Efficiency | % | >98 | ||||||||||||||||

| Fuel Available | Diesel and gas fuels | |||||||||||||||||

| Oil(Gas) Consumption |

Kg/H | 260 | 388 | 629 | 640 | 660 | 960 | 980 | 1000 | 1258 | 1298 | 1358 | 1572 | 1622 | 1672 | 2202 | 2272 | 2342 |

| Nm³/h | 310 | 465 | 760 | 780 | 800 | 1140 | 1160 | 1180 | 1520 | 1560 | 1600 | 1900 | 1950 | 2000 | 2660 | 2730 | 2800 | |

| Ringelmann blackness | <Lingerman Levell | |||||||||||||||||

| Main Steam Valre Bore | mm | 100 | 125 | 150 | 200 | 200 | 200 | 250 | 250 | 250 | ||||||||

| Safety Valve Bore | mm | 50 | 65 | 80 | 100 | 125 | 125 | 125 | 125 | 125 | ||||||||

| Inlet Valve Bore | mm | 40 | 50 | 50 | 65 | 80 | 80 | 80 | 80 | 100 | ||||||||

| Liquid Indicator Bore | mm | 25 | ||||||||||||||||

| Combustion mode | chamber combustion | |||||||||||||||||

| Transport,weightoflarge pieces | t | 25 | 30 | 37 | 38 | 40 | 43 | 45 | 46 | 48 | 50 | 53 | 58 | 60 | 63 | 71 | 73 | 76 |

| Transport Dimension | m | 5.3x3x3.3 | 6x3.2x3.4 | 6.8x3.4x3.54 | 7.8x3.6x3.8 | 8.8x1.4x4 | 10.5x4.2x4.1 | 13x4.5x4.2 | ||||||||||