+86-17757929999

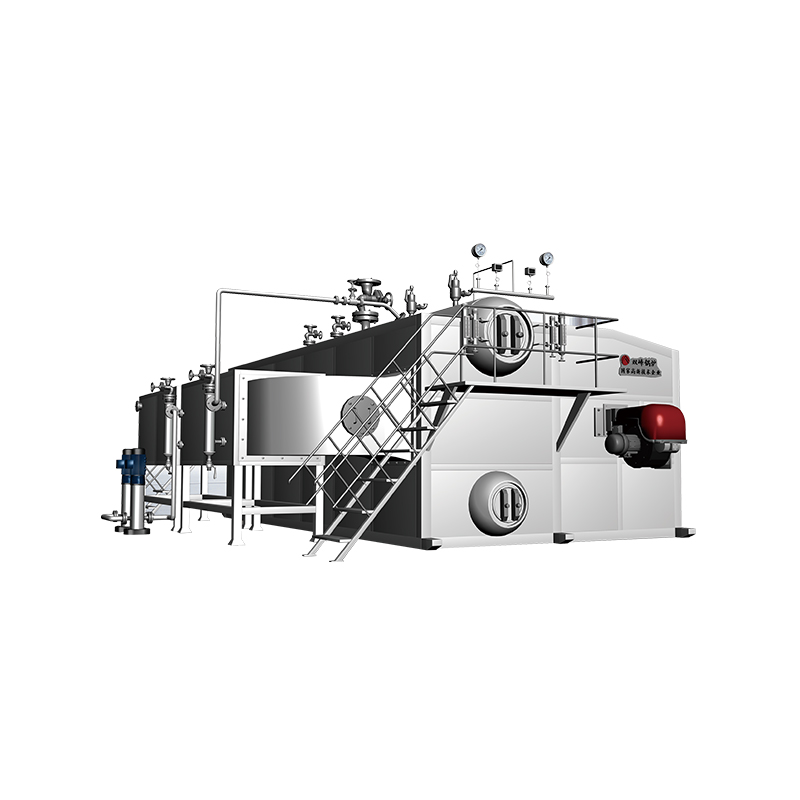

In industrial production, the Gas/Oil Steam Boiler remains a widely used solution for providing reliable steam to manufacturing processes. Recent trends show that factories are examining efficiency, emissions, and operational flexibility when selecting new or replacement boilers. Reports suggest that mid-sized gas and oil steam boilers in factories range from 500 kW to 15 MW capacity, capable of supporting a wide range of process applications from food production to chemical manufacturing.

Gas/Oil Steam Boiler installation considerations in factories

Factory managers often ask: what requirements must be met for safe and effective boiler installation? Gas and oil steam boilers require dedicated fuel supply lines, ventilation for combustion, proper flue design, and appropriate condensate and steam piping. Space planning and structural support are also important for high-capacity units. Proper planning ensures energy distribution is optimized and plant safety standards are maintained.

Gas/Oil Steam Boiler operational efficiency and fuel consumption

Industrial engineers frequently compare performance metrics: how does a gas/oil boiler perform compared to other steam-generation methods? Modern gas-fired boilers can achieve thermal efficiency of approximately 90%, while advanced oil-fired units typically reach 85–88%. Fuel consumption per ton of steam can vary depending on load management, maintenance, and fuel quality. In some plants, switching from outdated oil-fired boilers to modern gas-fired systems reduced fuel costs by up to 20% and improved load responsiveness. These improvements directly impact production consistency, especially in factories requiring stable steam temperature and pressure.

Gas/Oil Steam Boiler emissions and regulatory factors

Industrial operations ask: how do emissions from gas/oil boilers affect compliance? Oil-fired boilers generally emit higher levels of NOₓ and SO₂ compared to gas-fired units. Regulatory requirements in industrial zones often impose limits on these pollutants. Factories implementing gas-fired boilers reduce the likelihood of exceeding emission thresholds and may simplify operational permitting. Monitoring emissions and maintaining burner efficiency is critical to align with environmental standards while minimizing downtime.

Gas/Oil Steam Boiler maintenance and operational reliability

Another common consideration is maintenance: how often do gas/oil steam boilers require inspection and servicing? Regular checks of burners, heat exchangers, and fuel supply lines ensure consistent steam output and prevent unplanned shutdowns. Reports indicate that scheduled maintenance every 6–12 months maintains efficiency levels and extends equipment life. In high-demand manufacturing lines, consistent boiler performance reduces production interruptions and supports overall plant productivity.

Gas/Oil Steam Boiler future prospects in industrial plants

Looking forward, factories are asking: what role will gas and oil steam boilers play in evolving industrial energy strategies? Although electric and biomass boilers are gaining attention, gas and oil steam boilers remain practical for plants with established fuel infrastructure or high heat demand. Newer models integrate digital control, automated safety systems, and modular design for flexible operation. These improvements make gas/oil steam boilers relevant for industrial plants balancing cost, efficiency, and operational reliability.

In conclusion the Gas/Oil Steam Boiler continues to serve as a dependable component in industrial steam systems. Plants adopting modern units can realize improved efficiency, reduced fuel consumption, and better regulatory compliance. For engineers and facility managers planning steam upgrades, the Gas/Oil Steam Boiler offers a pragmatic balance of performance, cost, and operational reliability.

And so the Gas/Oil Steam Boiler maintains a key role in industrial steam production strategy.