+86-17757929999

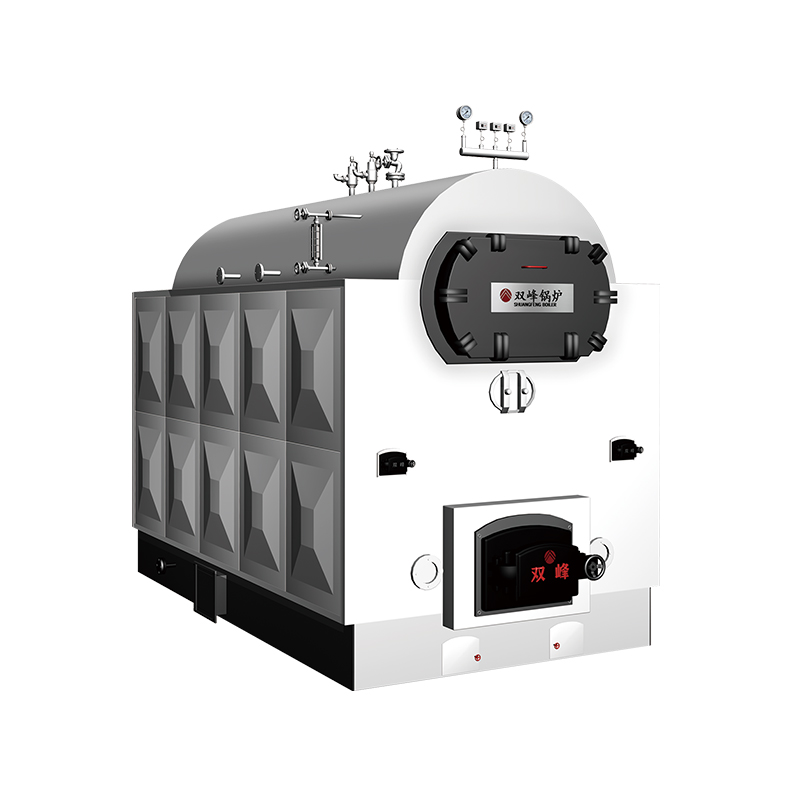

In industrial settings where renewable inputs are important, the Biomass Steam Boiler is an element of energy infrastructure that connects fuel flexibility with operational needs. Designed to use solid biomass fuels such as wood chips, agricultural residues, and pellets, these boilers can generate steam to support processes such as material drying, chemical heating, and facility thermal systems. Typical units range in steam output from less than one ton per hour to over 20 tons per hour, serving medium‑scale manufacturing facilities that require reliable thermal inputs.

One area of focus among operators is the way biomass boilers handle diverse fuel characteristics. Agricultural residues, wood products, and composite biomass pellets differ in moisture content, energy density, and ash production. Boiler designs address these differences through adjustable feeding systems and multi‑stage combustion chambers that promote complete combustion and better heat transfer. Fuel adaptability reduces waste streams for facilities that manage varied biomass waste, helping align fuel handling with existing material flows.

Emissions control and regulatory compliance are active themes in discussions about industrial boiler deployment. Newer boiler systems often include advanced particulate and gas control modules that reduce soot and nitrogen oxide levels to meet regional requirements. These systems may include cyclone separators or multi‑stage filters to collect fine particles before flue gases are released. Compliance helps facilities remain in good standing with environmental standards while supporting steam‑driven operations.

Operators also pay attention to boiler auxiliary systems. Efficiency in steam production is affected by feedwater systems, refractory linings, control systems, and maintenance protocols. For example, economizer components that recover exhaust heat for preheating incoming water can reduce the fuel required to generate steam. Digital control systems can optimize combustion air flows to match real‑time conditions, refining fuel use and reducing operational variability.

Additionally, biomass steam boilers are increasingly integrated with distributed energy systems. In some facilities, they support combined heat and power units, providing both steam for process heat and hot water or electricity for internal use. Heat distribution networks can supply multiple production areas simultaneously, and modular boiler arrangements allow plants to adjust output to seasonal or operational demand without interrupting critical processes. Monitoring systems provide operators with real‑time data on combustion efficiency, steam pressure, and fuel consumption, enabling informed decision-making.

Biomass Steam Boiler installations have been used in industries such as textiles, food processing, chemical production, and materials manufacturing, where steam quality and availability influence both product outcomes and throughput. In many cases, operators report that integrating biomass boilers with existing thermal systems allows a smoother transition from fossil fuels to bio‑based energy flows. As facilities strive to align thermal generation with internal sustainability goals, this type of boiler remains a practical energy source where biomass feedstocks are accessible.

Frequently Asked Questions

Q: What fuels can a biomass steam boiler use?

A: Biomass steam boilers typically burn wood chips, agricultural residues, and compacted biomass pellets.

Q: What industries use these boilers?

A: They find applications in textiles, food and beverage, chemical processing, and building material sectors.

Q: Does fuel quality affect performance?

A: Yes; moisture content and energy density of biomass fuels influence combustion and heat output.

Q: Can emissions be controlled?

A: Modern systems include filters and multi‑stage controls to manage particulate and gas emissions.

Q: How is steam temperature regulated?

A: Control systems and feedwater preheating elements help stabilize steam output.