+86-17757929999

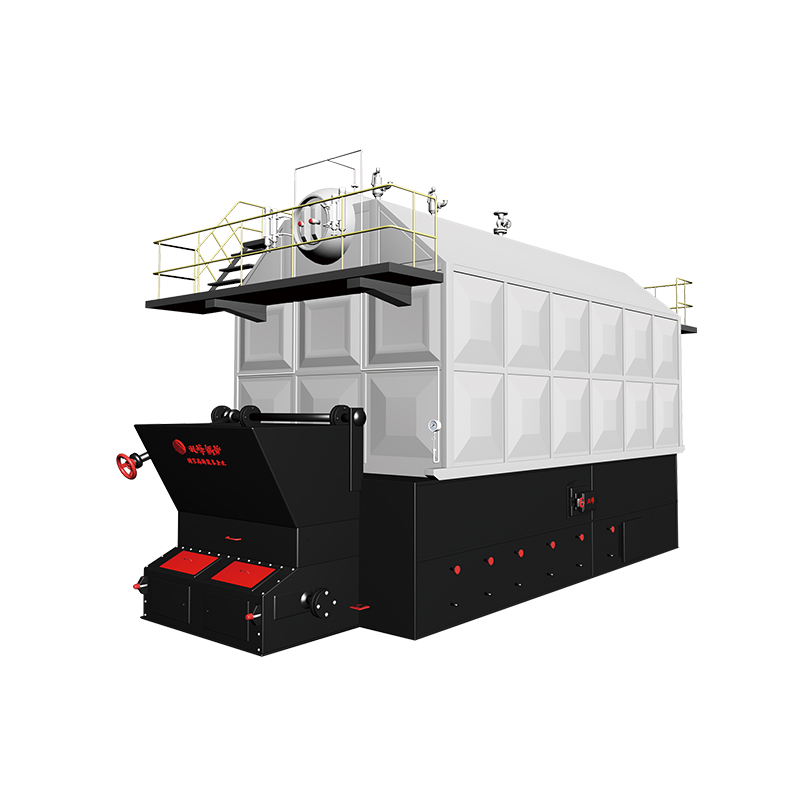

Biomass steam boilers are increasingly recognized as a practical solution for industries seeking reliable heat and steam generation while utilizing renewable energy sources. Designed to burn organic materials such as wood chips, agricultural residues, and energy crops, these boilers offer a versatile option for industrial and commercial applications.

In the industrial sector, biomass steam boilers are widely used for process heating, power generation, and combined heat and power (CHP) systems. According to a recent market analysis, approximately 45% of small to medium-sized industrial plants in Europe and Asia have integrated biomass boilers to supplement conventional energy sources. Applications range from food processing and pulp and paper production to textile and chemical manufacturing, where consistent steam supply is crucial for operational efficiency.

One of the defining features of biomass steam boilers is their ability to adapt to multiple fuel types. Modern boilers employ chain grate or fluidized bed technologies, which allow operators to burn a mix of wood pellets, rice husks, and other agricultural residues with high efficiency. Efficiency levels for well-maintained systems typically reach 85–90%, making biomass boilers a competitive option compared to traditional coal-fired boilers. Additionally, the adoption of automated feeding systems and digital control units has improved operational safety and reduced the need for constant manual supervision.

Environmental considerations are a significant factor in the deployment of biomass steam boilers. By using renewable organic fuel, these systems help reduce reliance on fossil fuels and contribute to lower carbon emissions. Studies indicate that a biomass boiler can reduce CO₂ emissions by up to 30% compared to coal-fired equivalents. Furthermore, biomass boilers often comply with local emission standards, as advanced designs incorporate low-NOx burners and flue gas treatment technologies to minimize particulate output.

The global market for biomass boilers reflects growing interest in sustainable industrial energy. In Asia-Pacific regions, governmental incentives and renewable energy policies have encouraged wider adoption, while European initiatives emphasize both renewable heat and circular economy benefits. Agricultural residues that might otherwise be discarded can be transformed into energy, supporting both economic and environmental goals.

Despite their advantages, biomass steam boilers require careful planning and maintenance. Proper fuel storage, regular inspection of the combustion chamber, and monitoring of boiler efficiency are critical for long-term performance. Facilities also need to consider logistical factors, such as fuel availability and transportation, to ensure uninterrupted operation.

FAQ

Q1: What types of biomass can be used in a biomass steam boiler?

A1: Common fuels include wood chips, pellets, rice husks, straw, and other agricultural residues. Some systems can also burn energy crops and mixed organic waste.

Q2: What is the typical efficiency of a biomass steam boiler?

A2: Modern biomass boilers typically achieve thermal efficiencies of 85–90% under normal operating conditions.

Q3: Are biomass steam boilers environmentally friendly?

A3: Yes, they reduce reliance on fossil fuels and can lower CO₂ emissions by around 30% compared to coal-fired boilers.

Q4: What maintenance is required for biomass boilers?

A4: Regular cleaning of the combustion chamber, inspection of moving parts, fuel quality checks, and monitoring of system performance are recommended.

This approach highlights practical applications, technological considerations, and environmental benefits, positioning Biomass Steam Boiler as an effective solution for industries aiming for energy efficiency and sustainability.